- Product description

- Major function

- Basic parameter

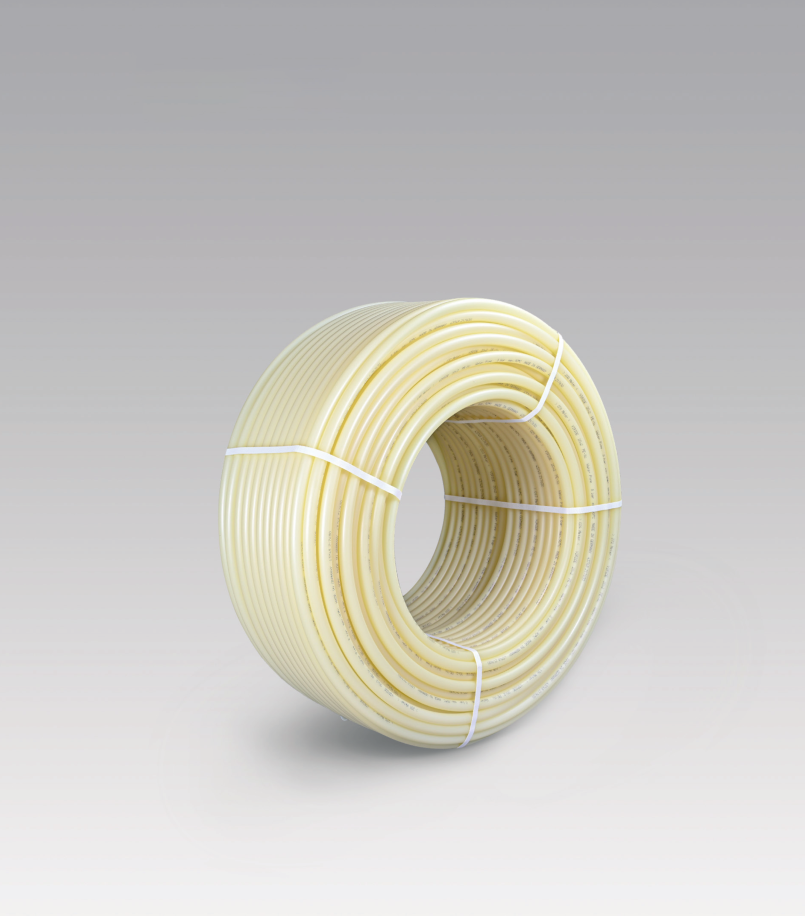

PP-R Aluminum-Plastic Composite Pipe: Inner layer, Outer layer is random copolymer polypropylene (PPR), embedded in metal welded aluminum alloy pipe, through the interlayer

Hot-melt adhesives form a bonding layer with a fusible outer layer of composite pipes.

Performance characteristics:

1. Hygienic and non-toxic: the inner layer and the outer layer are random copolymerized polypropylene (PPR). No lead-containing heavy metals and stabilizers are added in the processing, and there is no toxicity. The hygienic index meets the requirements of GB/T17219 standard.

2. Corrosion resistance: It can withstand acid and alkali corrosion with PH value between 1 and 14 in a wide temperature range.

3. No scaling: Smooth inner wall, no scaling, 30% higher than the flow rate of metal pipe.

4. Heat preservation and energy saving: the thermal conductivity is only 2% of that of metal pipes, which is very effective for heat preservation and energy saving of hot water pipes.

5. Low coefficient of expansion: Because of the aluminum layer in the middle, the linear coefficient of expansion is small. It has the same strength as the metal pipe, good toughness and impact resistance. The position of the pipe can be measured by metal detector.

6. Light weight, only one seventh of the specific gravity of metal pipes, easy to cut and process.